Page 396 - Softbound_Edition_19_en

P. 396

Proportional spool valve

Proportional spool valve Proportional spool valve

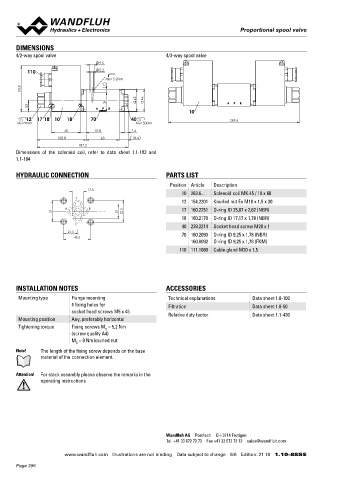

DIMENSIONS Proportional spool valve with additional hand

4/2-way spool valve 4/3-way spool valve lever actuation NG6

9.5 ISO 4401-03

Flange construction

110 5.2 ◆ Q = 35 l/min x II 2 G Ex db IIC

max

MD= 5.2Nm ◆ 4 volume flow levels x II 2 D Ex tD A21 IP65

93.8 7 ◆ Q N max = 25 l/min x I M2 Ex db I Mb

p = 350 bar

◆

Class I Division 1

45 46 max Class I Zone 1

39

23

10

12 17 18 10 18 70 40 269.6

MD=9Nm MD=50Nm

60 10.8 7.6 DESCRIPTION SYMBOL

100.8 68 18.4 Proportional spool valve according to data sheet 1.10-88 with addi- Overview spool types see data sheet 1.10-88

187.2 tional hand lever actuation.

Dimensions of the solenoid coil, refer to data sheet 1.1-183 and Note! The standard valve cannot be retrofitted.

1.1-184

A B

HYDRAULIC CONNECTION PARTS LIST a 0 b

Position Article Description a P T b

17.8

10 263.6... Solenoid coil MK.45 / 18 x 60

T

12 154.2201 Knurled nut Ex M18 x 1,5 x 30 TYPE CODE

A B 17 160.2251 O-ring ID 25,07 x 2,62 (NBR)

31 21 32.5 WD B F A06 - Z568 # 2

18 160.2170 O-ring ID 17,17 x 1,78 (NBR) Spool valve, direct operated

P

40 239.2214 Socket head screw M20 x 1

21.5 70 160.2093 O-ring ID 9,25 x 1,78 (NBR) Proportional, explosion proof execution Ex d

40.5 Flange construction

160.8092 O-ring ID 9,25 x 1,78 (FKM)

110 111.1080 Cable gland M20 x 1,5 International standard interface ISO NG6

Other type designation according to type code data sheet 1.10-88

Hand lever

INSTALLATION NOTES ACCESSORIES Design index (subject to change)

1.10-89

Mounting type Flange mounting Technical explanations Data sheet 1.0-100

4 fixing holes for Filtration Data sheet 1.0-50

socket head screws M5 x 45 Relative duty factor Data sheet 1.1-430 DIMENSIONS GENERAL SPECIFICATIONS

Mounting position Any, preferably horizontal Weight WDBFA06 +1,0 kg

Tightening torque Fixing screws M = 5,2 Nm Note! Further specifications, see data sheet 1.10-88

D

(screw quality A4)

M = 9 Nm knurled nut

D

Note! The length of the fixing screw depends on the base

material of the connection element.

256.5

SURFACE TREATMENT

Attention! For stack assembly please observe the remarks in the

operating instructions ◆ The flange, the housing and the lever are zinc-nickel coated

44.4

167.9 123.5

291.4

Wandfluh AG Postfach CH-3714 Frutigen Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 [email protected] Tel. +41 33 672 72 72 Fax +41 33 672 72 12 [email protected]

www.wandfluh.com Illustrations are not binding Data subject to change 6/6 Edition: 21 18 1.10-88S E www.wandfluh.com Illustrations are not binding Data subject to change 1/1 Edition: 19 38 1.10-89 E

Page 396