Page 390 - Softbound_Edition_19_en

P. 390

Proportional spool valve

Proportional spool valve Proportional spool valve

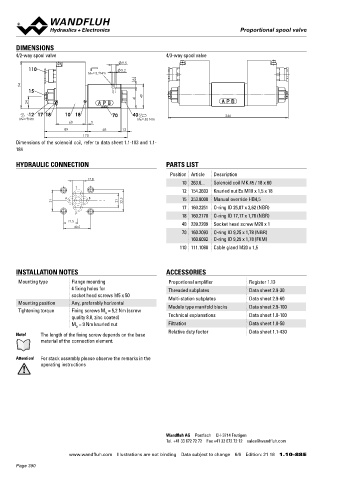

DIMENSIONS Proportional spool valve stainless

4/2-way spool valve 4/3-way spool valve Flange construction NG6

9.5 Q = 30 l/min ISO 4401-03

110 5.2 ◆ max

MD= 5.2Nm ◆ 3 volume flow levels x II 2 G Ex db IIC T6, T4

8 ◆ Q N max = 20 l/min x II 2 D Ex tb III C T80 °C, T130 °C

94 ◆ p = 350 bar x I M2 Ex db I Mb

15 max Class I Division 1

41 49 Class I Zone 1

24

12 17 18 10 18 70 40 246

MD=9Nm MD=50 Nm

60 5

89 68 13 DESCRIPTION APPLICATION

170 Direct operated proportional spool valve with 4 connections in These valves are suitable for applications in explosion-hazard areas,

Dimensions of the solenoid coil, refer to data sheet 1.1-183 and 1.1- 5-chamber system. Precise spool fit, low leakage, long service life open cast and also in mines. The stainless execution is especially

184 time. Proportional to the solenoid current, the spool stroke, the spool suitable for the use in wet and salty environment. Proportional spool

opening and the valve volume flow increase. The pressure tight en- valves are perfectly suitable for demanding tasks due to the high re-

HYDRAULIC CONNECTION PARTS LIST capsulated Ex-protection solenoid coil prevents an explosion on the solution, large volume flow and low hysteresis. The applications are

Position Article Description inside penetrating to the outside as well as an ignitable surface tem- in the industrial as well as in the mobile hydraulics for the smooth

17.8 perature. control of hydraulic actuations.

10 263.6... Solenoid coil MK.45 / 18 x 60

T

12 154.2603 Knurled nut Ex M18 x 1,5 x 18

A B 15 253.8000 Manual override HB4,5

31 21 32.5

17 160.2251 O-ring ID 25,07 x 2,62 (NBR)

P 18 160.2170 O-ring ID 17,17 x 1,78 (NBR) CERTIFICATES ACTUATION

21.5 40 239.2209 Socket head screw M20 x 1 Surface Mining Standard M248 Actuation Proportional solenoid, wet pin push

40.5 -25 °C Electronic type, pressure tight

70 160.2093 O-ring ID 9,25 x 1,78 (NBR) to… Execution MKY45 / 18x60 (data sheet 1.1-183)

160.6092 O-ring ID 9,25 x 1,78 (FKM) ATEX x x x x MKU45 / 18x60 (data sheet 1.1-184)

110 111.1080 Cable gland M20 x 1,5 Connection Cable gland for cable Ø 6,5…14 mm

IECEx x x x x

CCC x x x x Attention! The UL execution is always supplied without cable

EAC x x x x gland

INSTALLATION NOTES ACCESSORIES

Australia x x x

Mounting type Flange mounting Proportional amplifier Register 1.13 MA x x x

4 fixing holes for Threaded subplates Data sheet 2.9-30 UL / CSA x x

socket head screws M5 x 50 Multi-station subplates Data sheet 2.9-60

Mounting position Any, preferably horizontal Module type manifold blocks Data sheet 2.9-100 The certificates can be found on www.wandfluh.com

Tightening torque Fixing screws M = 5,2 Nm (screw

D

quality 8.8, zinc coated) Technical explanations Data sheet 1.0-100 SYMBOL

M = 9 Nm knurled nut Filtration Data sheet 1.0-50 Symmetrical control

D

Relative duty factor Data sheet 1.1-430

Note! The length of the fixing screw depends on the base ACB-S AC1-S CB2-S

material of the connection element.

A B A B A B

Attention! For stack assembly please observe the remarks in the a 0 b a b

operating instructions a b a b a b

P T P T P T

Meter-in control

ADB-V AD1-V DB2-V

A B A B A B

a b a b

a b a b a b

P T P T P T

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 [email protected]

www.wandfluh.com Illustrations are not binding Data subject to change 6/6 Edition: 21 18 1.10-88 E www.wandfluh.com Illustrations are not binding Data subject to change 1/6 Edition: 21 18 1.10-88S E

Page 390