Page 574 - Softbound_Edition_19_en

P. 574

Solenoid operated poppet valve Solenoid operated poppet valve

Poppet valve

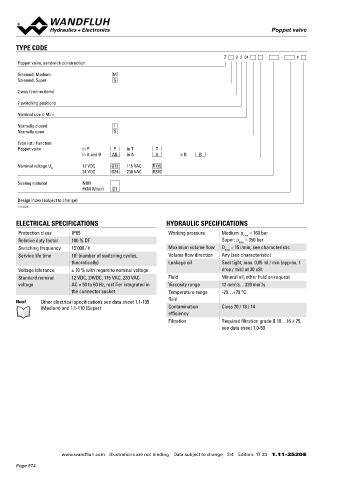

TYPE CODE PERFORMANCE SPECIFICATIONS

2

Z 2 2 04 - - # Oil viscosity u = 30 mm /s

Poppet valve, sandwich construction Δp = f (Q) Pressure drop volume-flow characteristics p = f (Q) Performance limits „Medium”

Measured with nominal voltage -10 %

Solenoid, Medium M

Solenoid, Super S p [bar] p [bar]

40 K0154 160 K0152

2 way (connections) 35 140

30 120

2 switching positions 25 100

20 80

15 60

Nominal size 4-Mini 10 40

5 20

Normally closed 1 0 0

Normally open 0 0 2 4 6 8 10 12 14 16 Q [l/min] 0 2 4 6 8 10 12 14 16 Q [l/min]

Type list / Function

Poppet valve in P P in T T p = f (Q) Performance limits „Super” Flow direction

in A and B AB in A A in B B

Measured with nominal voltage -10 % Type 1 → 2 2 → 1

Nominal voltage U N 12 VDC G12 115 VAC R115 p [bar] ZS22041. 1 3

24 VDC G24 230 VAC R230 350 K0338 3 2 1 ZS22040. 1 3

300

Sealing material NBR 250

FKM (Viton) D1 200

150

Design index (subject to change) 100

1.11-2520 Attention! Long periods of non-actuation can reduce the switching

50

0 performance

ELECTRICAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS 0 2 4 6 8 10 12 14 16 Q [l/min]

Protection class IP65 Working pressure Medium: p = 160 bar

max

Relative duty factor 100 % DF Super: p = 350 bar STANDARDS ACCESSORIES

max

Switching frequency 15'000 / h Maximum volume flow Q = 15 l/min, see characteristic Mounting interface Wandfluh standard Fixing screws Data sheet 1.0-60

max

7

Service life time 10 (number of switching cycles, Volume flow direction Any (see characteristic) Solenoids DIN VDE 0580 Threaded subplates Data sheet 2.9-05

theoretically) Leakage oil Seat tight, max. 0,05 ml / min (approx. 1 Connection execution D EN 175301 – 803 Multi-station subplates Data sheet 2.9-45

Voltage tolerance ± 10 % with regard to nominal voltage drop / min) at 30 cSt Protection class EN 60 529 Horizontal mounting blocks Data sheet 2.9-85

Standard nominal 12 VDC, 24VDC, 115 VAC, 230 VAC Fluid Mineral oil, other fluid on request Contamination efficiency ISO 4406

voltage AC = 50 to 60 Hz, rectifier integrated in Viscosity range 12 mm /s…320 mm /s Technical explanations Data sheet 1.0-100

2

2

the connector socket Temperature range -20…+70 °C Hydraulic fluids Data sheet 1.0-50

fluid MANUAL OVERRIDE Filtration Data sheet 1.0-50

Note! Other electrical specifications see data sheet 1.1-105 Screw plug (HB0), no actuation possible

(Medium) and 1.1-110 (Super) Contamination Class 20 / 18 / 14 Optionally: HB4,5, HN(K) or HR(K) Relative duty factor Data sheet 1.1-430

efficiency → See data sheet 1.1-311

Filtration Required filtration grade ß 10…16 ≥ 75,

see data sheet 1.0-50

COMMISSIONING SEALING MATERIAL

Attention! When commissioning, the valve must be vented under NBR or FKM (Viton) as standard, choice in the type code

pressure (max. two rotations of screw E).

SURFACE TREATMENT INSTALLATION NOTES

◆ The sandwich bodies made of steel are zinc-phosphated Mounting type Sandwich mounting

◆ The solenoid and the cover are zinc coated 3 fixing holes for

◆ The socket head screws are zinc coated socket head screws or studs M5

Mounting position Any, preferably horizontal

Tightening torque Fixing screws M = 5,2 Nm (screw

D

quality 8.8, zinc coated)

VALVES INSTALLED

The central functioning element is the poppet valve cartridge NG4, data sheet 1.11-2020.

www.wandfluh.com Illustrations are not binding Data subject to change 2/4 Edition: 17 33 1.11-2520 E www.wandfluh.com Illustrations are not binding Data subject to change 3/4 Edition: 17 33 1.11-2520 E

Page 574