Page 222 - Softbound_Edition_19_en

P. 222

Solenoid operated spool valve

Solenoid operated spool valve Solenoid operated spool valve

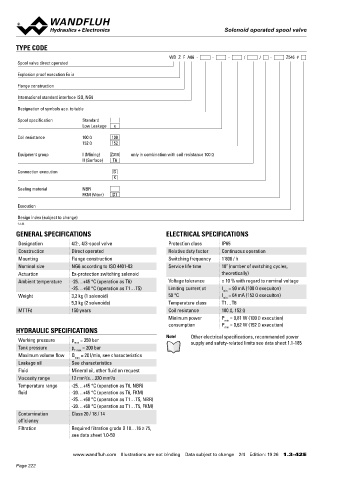

TYPE CODE PERFORMANCE SPECIFICATIONS

2

WD Z F A06 - - - / / - Z546 # Oil viscosity u = 30 mm /s

Spool valve direct operated p = f (Q) Performance limits 100 Ω p = f (Q) Performance limits 152 Ω

Explosion proof execution Ex ia p [bar] AB_/ACB ADB AB3 p [bar] AB_ / ACB AB3

350 K1181 350 K4208 ADB

Flange construction 300 300

250 250

International standard interface ISO, NG6 200 200

150 150

Designation of symbols acc. to table 100 100

50 50

Spool specification Standard 0 0

Low Leakage x 0 4 8 12 16 20 Q [l/min] 0 4 8 12 16 20 Q [l/min]

Coil resistance 100 Ω 100

152 Ω 152

Δp = f (Q) Pressure drop volume flow characteristic Q = f (p) Leakage volume flow characteristic

L

Equipment group I (Mining) Z319 only in combination with coil resistance 100 Ω P → T

II (Surface) T6

p [bar] Q [cm /min] Standard

3

Connection execution D 50 K1182 80 K1183

K 40

60

Sealing material NBR 30

FKM (Viton) D1 20 40

10 20

Execution

0 0

Design index (subject to change) 0 4 8 12 16 20 Q [l/min] 0 50 100 150 200 250 300 350 p [bar]

1.3-42

3

GENERAL SPECIFICATIONS ELECTRICAL SPECIFICATIONS Attention! If, because of the given operating conditions, during the 80 Q [cm /min] Low leakage

Designation 4/2-, 4/3-spool valve Protection class IP65 switching process volume flows occur which exceed

Construction Direct operated Relative duty factor Continuous operation the power limit of the valve, these have to be limited by 60

a throttle or an orifice in connection P.

Mounting Flange construction Switching frequency 1'800 / h In case of a continuous flow through, the throttle or 40

Nominal size NG6 according to ISO 4401-03 Service life time 10 (number of switching cycles, orifice, depending on the system behaviour, an 20

7

Actuation Ex-protection switching solenoid theoretically) additional heating-up of the valve is possible. This has 0

Ambient temperature -25…+45 °C (operation as T6) Voltage tolerance ± 10 % with regard to nominal voltage to be appropriately taken into account by the user. 0 50 100 150 200 250 300 350 p [bar]

-25…+60 °C (operation as T1…T5) Limiting current at I = 90 mA (100 Ω execuiton)

min

Weight 3,2 kg (1 solenoid) 50 °C I = 64 mA (152 Ω execuiton)

min

5,3 kg (2 solenoids) Temperature class T1…T6 ACCESSORIES MANUAL OVERRIDE

MTTFd 150 years Coil resistance 100 Ω, 152 Ω HB4,5 as standard

Minimum power P = 0,81 W (100 Ω execution) Fixing screws Data sheet 1.0-60

min

consumption P = 0,62 W (152 Ω execution) Threaded subplates Data sheet 2.9-10

HYDRAULIC SPECIFICATIONS min Multi-station subplates Data sheet 2.9-50

Note! Other electrical specifications, recommended power

Working pressure p = 350 bar Module type manifold blocks Data sheet 2.9-90

max supply and safety-related limits see data sheet 1.1-185

Tank pressure p = 200 bar Technical explanations Data sheet 1.0-100 SEALING MATERIAL

T max

Maximum volume flow Q = 20 l/min, see characteristics Filtration Data sheet 1.0-50 NBR or FKM (Viton) as standard, choice in the type code

max

Leakage oil See characteristics Relative duty factor Data sheet 1.1-430

Fluid Mineral oil, other fluid on request

Viscosity range 12 mm /s…320 mm /s

2

2

Temperature range -25…+45 °C (operation as T6, NBR)

fluid -20…+45 °C (operation as T6, FKM) STANDARDS SURFACE TREATMENT

-25…+60 °C (operation as T1…T5, NBR) Explosion protection Directive 2014 / 34 / EU (ATEX) ◆ The valve body is painted with a two component paint

-20…+60 °C (operation as T1…T5, FKM) ◆ The armature tube, the slip-on coil and the plug screw are

Contamination Class 20 / 18 / 14 Mounting interface ISO 4401-03 zinc-nickel coated

EN 60 529

Protection class

efficiency

Filtration Required filtration grade ß 10…16 ≥ 75, Contamination ISO 4406

see data sheet 1.0-50 efficiency

www.wandfluh.com Illustrations are not binding Data subject to change 2/4 Edition: 19 26 1.3-42 E www.wandfluh.com Illustrations are not binding Data subject to change 3/4 Edition: 19 26 1.3-42 E

Page 222