Page 376 - Softbound_Edition_19_en

P. 376

Proportional spool valve

Proportional spool valve Proportional spool valve

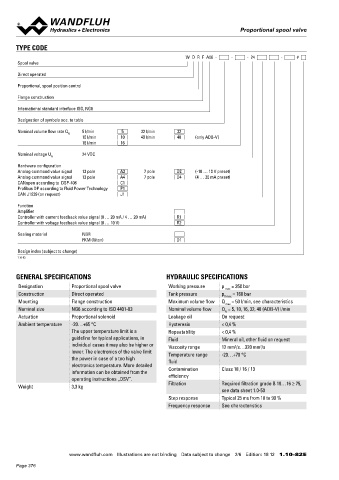

TYPE CODE ELECTRICAL CONNECTION

W D R F A06 - - - 24 - # X1 Analog interface (Main) X1 Fieldbus interface (Main)

Spool valve

Device receptacle M23, 12 pole male Device receptacle M12, 4 pole male

Direct operated 1 = Supply voltage + 2 1 1 = Supply voltage +

8 9 1 2 = Supply voltage 0 VDC 3 4 2 = Reserved for extentions

Proportional, spool position control 7 12 10 2 3 = Stabilised output voltage 3 = Supply voltage 0 VDC

6 11 3

5 4 4 = Command value signal voltage + 4 = Chassis

Flange construction

5 = Command value signal voltage -

International standard interface ISO, NG6 6 = Command value signal current +

7 = Command value signal current -

Designation of symbols acc. to table 8 = Reserved for extentions

9 = Reserved for extentions

Nominal volume flow rate Q N 5 l/min 5 32 l/min 32 10 = Enable signal (Digital input) X2 Parameterisation interface

10 l/min 10 40 l/min 40 (only ADB-V)

16 l/min 16 11 = Error signal (Digital output) USB, Mini B Under the screw plug of the housing

12 = Chassis cover

Nominal voltage U 24 VDC Factory set

N Command value signal voltage (PIN 4/5) resp. current (PIN 6/7) are

selected with parameterisation and diagnostics software PASO.

Hardware configuration

Analog command value signal 12 pole A2 7 pole D2 (-10 … 10 V preset) Factory setting: voltage (-10… +10 V), (PIN 4/5)

Analog command value signal 12 pole A4 7 pole D4 (4 … 20 mA preset)

CANopen according to DSP-408 C1

Profibus DP according to Fluid Power Technology P1 X1 Analog interface (Main) X3 Profibus interface according to IEC

CAN J1939 (on request) J1

Connector DIN EN 175201 - 804 947-5-2

Function Device receptacle 7 pole male Device receptacle M12, 5 pole female B-coded

Amplifier A = Supply voltage + 2 3 1 = VP

Controller with current feedback value signal (0 … 20 mA / 4 … 20 mA) R1 A B = Supply voltage 0 VDC 5 2 = RxD / TxD - N

Controller with voltage feedback value signal (0 … 10 V) R2 F G B C = Analog output - 1 4 3 = DGND

E C

Sealing material NBR D D = Command value signal + 4 = RxD / TxD - P

FKM (Viton) D1 E = Command value signal - 5 = Shield

F = Analog output +

Design index (subject to change) G = Chassis

1.10-82

Command value signal: current (D4) or voltage (D2) to specify

when placing the order

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

Designation Proportional spool valve Working pressure p = 350 bar

max X3 CANopen interface according to DRP X4 (controller only) Feedback value interface (sensor)

Construction Direct operated Tank pressure p = 160 bar 303-1

T max Device receptacle M12, 5 pole female

Mounting Flange construction Maximum volume flow Q = 50 l/min, see characteristics Device receptacle M12, 5 pole male 1 = Supply voltage (output) +

max 2 3

Nominal size NG6 according to ISO 4401-03 Nominal volume flow Q = 5, 10, 16, 32, 40 (ADB-V) l/min 1 = Not connected 5 2 = Feedback value signal +

N 2 1 1 4

Actuation Proportional solenoid Leakage oil On request 5 2 = Not connected 3 = Supply voltage 0 VDC

3 4

Ambient temperature -20…+65 °C Hysteresis < 0,4 % 3 = CAN Gnd 4 = Not connected

The upper temperature limit is a Repeatability < 0,4 % 4 = CAN High 5 = Stabilised output voltage

guideline for typical applications, in Fluid Mineral oil, other fluid on request 5 = CAN Low Feedback value signal: current (R1) or voltage (R2) to specify

individual cases it may also be higher or Viscosity range 12 mm /s…320 mm /s when placing the order

2

2

lower. The electronics of the valve limit Temperature range -20…+70 °C

the power in case of a too high fluid

electronics temperature. More detailed Contamination Class 18 / 16 / 13 Note! The mating connector is not included in the delivery

information can be obtained from the efficiency

operating instructions „DSV”.

Weight 3,3 kg Filtration Required filtration grade ß 10…16 ≥ 75,

see data sheet 1.0-50

Step response Typical 25 ms from 10 to 90 %

Frequency response See characteristics

www.wandfluh.com Illustrations are not binding Data subject to change 2/6 Edition: 18 12 1.10-82 E www.wandfluh.com Illustrations are not binding Data subject to change 3/6 Edition: 18 12 1.10-82 E

Page 376