Page 381 - Softbound_Edition_19_en

P. 381

Proportional spool valves

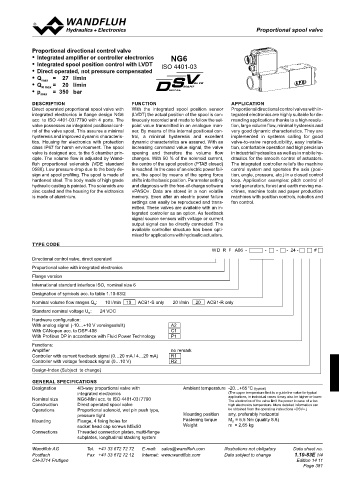

Proportional spool valve

Proportional directional control valve

• Integrated amplifier or controller electronics NG6

• Integrated spool position control with LVDT ISO 4401-03

• Direct operated, not pressure compensated

• Q max = 27 l/min

• Q N max = 20 l/min

• p max = 350 bar

DESCRIPTION FUNCTION APPLICATION

Direct operated proportional spool valve with With the integrated spool position sensor Proportional directional control valves with in-

integrated electronics in flange design NG6 (LVDT) the actual position of the spool is con- tegrated electronics are highly suitable for de-

acc. to ISO 4401-03 / 7790 with 4 ports. The tinuously recorded and made to follow the set- manding applications thanks to a high resolu-

valve possesses an integrated positional cont- point value transmitted in an analogue man- tion, large volume flow, minimal hysteresis and

rol of the valve spool. This assures a minimal ner. By means of this internal positional con- very good dynamic characteristics. They are

hysteresis and improved dynamic characteris- trol, a minimal hysteresis and excellent implemented in systems calling for good

tics. Housing for electronics with protection dynamic characteristics are assured. With an valve-to-valve reproducibility, easy installa-

class IP67 for harsh environment. The spool increasing command value signal, the valve tion, comfortable operation and high precision

valve is designed acc. to the 5 chamber prin- opening and therefore the volume flow in industrial hydraulics as well as in mobile hy-

ciple. The volume flow is adjusted by Wand- changes. With 50 % of the solenoid current, draulics for the smooth control of actuators.

fluh proportional solenoids (VDE standard the centre of the spool position (PTAB closed) The integrated controller reliefs the machine

0580). Low pressure drop due to the body de- is reached. In the case of an electric power fail- control system and operates the axis (posi-

sign and spool profiling. The spool is made of ure, the spool by means of the spring force tion, angle, pressure, etc.) in a closed control

hardened steel. The body made of high grade shifts into the basic position. Parameter setting loop. Application examples: pitch control of

hydraulic casting is painted. The solenoids are and diagnosis with the free-of-charge software wind generators, forest and earth moving ma-

zinc coated and the housing for the elctronics «PASO». Data are stored in a non volatile chines, machine tools and paper production

is made of aluminium. memory. Even after an electric power failure machines with position controls, robotics and

settings can easily be reproduced and trans- fan control.

mitted. These valves are available with an in-

tegrated controller as an option. As feedback

signal source sensors with voltage or current

output signal can be directly connected. The

available controller structure has been opti-

mised for applications with hydraulic actuators.

TYPE CODE

W D R F A06 - - - - 24 - #

Directional control valve, direct operated

Proportional valve with integrated electronics

Flange version

International standard interface ISO, nominal size 6

Designation of symbols acc. to table 1.10-83/2

: 10 l/min 10 ACB1-S only 20 l/min 20 ACB1-R only

Nominal volume flow ranges Q N

: 24 VDC

Standard nominal voltage U N

Hardware configuration:

With analog signal (-10…+10 V voreingestellt) A2

With CANopen acc. to DSP-408 C1

Wtih Profibus DP in accordance with Fluid Power Technology P1

Functions:

Amplifier no remark

Controller with current feedback signal (0…20 mA / 4…20 mA) R1

Controller with voltage feedback signal (0…10 V) R2

Design-Index (Subject to change)

GENERAL SPECIFICATIONS

Designation 4/3-way proportional valve with Ambient temperature -20…+65 °C (typical)

integrated electronics (The upper temperature limit is a guideline value for typical

Nominal size NG6-Mini acc. to ISO 4401-03 / 7790 applications, in individual cases it may also be higher or lower.

The electronics of the valve limit the power in case of a too

Construction Direct operated spool valve high electronics temperature. More detailed information can

Operations Proportional solenoid, wet pin push type, be obtained from the operating instructions «DSV».)

pressure tight Mounting position any, preferably horizontal

Mounting Flange, 4 fixing holes for Fastening torque M = 5,5 Nm (quality 8.8)

D

socket head cap screws M5x50 Weight m = 2,65 kg

Connections Threaded connection plates, multi-flange

subplates, longitudinal stacking system

Wandfluh AG Tel. +41 33 672 72 72 E-mail: [email protected] Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 1.10-83E 1/4

CH-3714 Frutigen Edition 14 11

Page 381