Page 459 - Softbound_Edition_19_en

P. 459

Poppet valve cartridges Poppet valve cartridges

Poppet valve cartridge

CHARACTERISTICS Oil viscosity υ = 30 mm /s

2

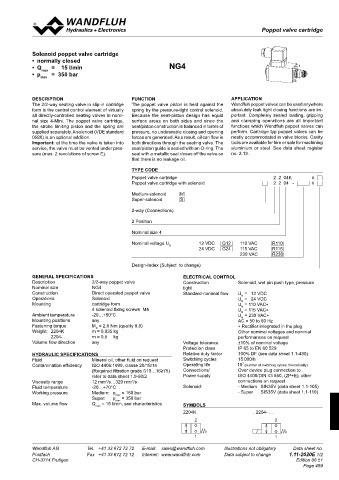

p = f (Q) Performance limit at -10% Solenoid poppet valve cartridge

p [bar] • normally closed

350 K0162 Flow direction • Q max = 15 l/min NG4

300 1 Type 1 → 2 2 → 1 • p max = 350 bar

250 M2203 3 3

200 3 2 S2203 1 2

150

100 deScRIptIoN FUNctIoN AppLIcAtIoN

50 The 2/2-way seating valve in slip-in cartridge The poppet valve piston is held against the Wandfluh poppet valves can be used anywhere

0 form is the central control element of virtually spring by the pressure-tight control solenoid. absolutely leak tight closing functions are im-

0 1 2 3 4 5 6 Q [l/min] all directly-controlled seating valves in nomi- Because the seat-piston design has equal portant. Completely sealed loading, gripping

nal size 4-Mini. The poppet valve cartridge, surface areas on both sides and since the and clamping operations are all important

∆p = f (Q) Pressure loss / flow characteristics the stroke limiting piston and the spring are seat/piston construction is balanced in terms of functions which Wandfluh poppet valves can

p [bar] supplied separately. A solenoid (VDE standard pressure, no undesirable closing and opening perform. Cartridge typ poppet valves can be

10 K0163 0580) is an optional addition. forces are generated. As a result, oil can flow in neatly accommodated in valve blocks. Cavity

Important: at the time the valve is taken into both directions through the seating valve. The tools are available for hire or sale for machining

8

service, the valve must be vented under pres- seat/piston guide is sealed with an O-ring. The aluminium or steel. See data sheet register

6 sure (max. 2 revolutions of screw E). seat with a metallic seal closes off the valve so no. 2.13.

4 that there is no leakage oil.

2 type code

0 Poppet valve cartridge 2 2 04K #

0 1 2 3 4 5 6 Q [l/min] Poppet valve cartridge with solenoid 2 2 04 - #

DIMENSIONS Medium-solenoid M

Super-solenoid S

. 2203- . . 2203

2-way (Connections)

2 Position

Nominal size 4

Nominal voltage U N 12 VDC G12 110 VAC R110

24 VDC G24 115 VAC R115

230 VAC R230

Design-Index (Subject to change)

GeNeRAL SpecIFIcAtIoNS eLectRIcAL coNtRoL

Description 2/2-way poppet valve Construction Solenoid, wet pin push type, pressure

Nominal size NG4 tight

Construction Direct operated poppet valve Standard-nominal flow U = 12 VDC

N

Operations Solenoid U N = 24 VDC

Mounting cartridge form U N = 110 VAC∗

For detailed cavity drawing 4 solenoid fixing screws M4 U N = 115 VAC∗

and cavity tools see data Ambient temperature -20…+50°C U N = 230 VAC∗

sheet 2.13-1012 Mounting positions any AC = 50 to 60 Hz

Fastening torque M = 2,6 Nm (quality 8.8) ∗ Rectifier integrated in the plug

D

Weight: 2204K m = 0,035 kg Other nominal voltages and nominal

PARTS LIST . 2204- . . m = 0,5 kg performances on request

Volume flow direction any Voltage tolerance ±10% of nominal voltage

∗ Cartridge supplied with fastening screw M3 x 40 for steel bodies/

Position Article Description Protection class IP 65 to EN 60 529

blocs. For aluminium bodies/blocs longer screws are recommended HydRAULIc SpecIFIcAtIoNS Relative duty factor 100% DF (see data sheet 1.1-430)

10 500.0002 Poppet valve cartridge 2203 (min. 2 screw diameter). Fluid Mineral oil, other fluid on request Switching cycles 15’000/h

11 052.1607 Spring 0,8 x 6 x 8 E = air bleed screw Contamination efficiency ISO 4406:1999, classe 20/18/14 Operating life 10 (number of switching cycles, theoretically)

7

12 222.0097 Pin (Required filtration grade ß10…16≥75) Connections/ Over device plug connection to

13 212.1580 Washer refer to data sheet 1.0-50/2 Power supply ISO 4400/DIN 43 650, (2P+E), other

2

2

14 160.2090 O-ring ID 9,00 x 1,00 Viscosity range 12 mm /s…320 mm /s Solenoid: connections on request

- Medium SIN35V (data sheet 1.1-105)

15 160.2093 O-ring ID 9,25 x 1,78 ACCESSORIES Fluid temperature -20…+70°C = 160 bar - Super SIS35V (data sheet 1.1-110)

Medium: p

Working pressure

16 160.1095 O-ring ID 9,50 x 1,6 Cartridge built-in flange- or sandwich body: Super: p max = 350 bar

max

20 260.2… Medium-solenoid SIN29V Flange Register 1.11 Max. volume flow Q = 15 l/min, see characteristics SyMBoLS

260.3… Super-solenoid SIS29V Sandwich Register 1.11 max

30 239.2033 Plug Special tool 983.2005 to poppet valve cartridge 2203 2204K . 2204- . .

(incl. seal) HB0

40 219.2002 Plug

50 246.0141 Socket head cap screw M3 x 40 DIN 912

Explications techniques voir feuille 1.0-100

Wandfluh AG Tel. +41 33 672 72 72 E-mail: [email protected] Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: [email protected] Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 1.11-2010E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 1.11-2020E 1/2

CH-3714 Frutigen Edition 05 02 CH-3714 Frutigen Edition 06 51

Page 459