Page 622 - Softbound_Edition_19_en

P. 622

Poppet valve

Poppet valve BH..04

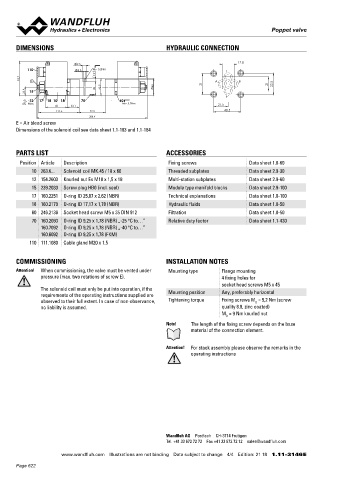

DIMENSIONS HYDRAULIC CONNECTION Poppet valve

Flange construction NG4-Mini

17.8 Wandfluh standard

9.5 ◆ hand operated

110 5.5 MD= 5.2Nm T 2/2-, 3/2- und 3/4-way

7.9 ◆

93.7 E 31 A B 21 32.5 ◆ normally open and normally closed

Q = 15 l/min

max

22.9 15 38 45.9 45 ◆ p = 350 bar

◆

P max

12 17 18 10 18 70 60

MD=9Nm MD= 5.2Nm 21.5

60 33.1

111.6 72.3 40.5

306.4 DESCRIPTION APPLICATION

E = Air bleed screw Direct operated 2/2-, 3/2 and 3/4-way poppet valve in flange Poppet valves are used where tight closing functions of the valve are

Dimensions of the solenoid coil see data sheet 1.1-183 and 1.1-184

construction. By means of the hand lever, the poppet valve spool is essential like leakage-free load holding, clamping or gripping. Minia-

opened or closed acting against the spring. Due to the poppet spool ture values are used where both, reduced dimensions and weight are

construction with pressure compensation on both sides, the flow important.

PARTS LIST ACCESSORIES through the valve is possible in both directions. The seat spool

Position Article Description Fixing screws Data sheet 1.0-60 guide is sealed by means of an O-ring. The metallically sealing seat

closes the valve virtually leak free.

10 263.6... Solenoid coil MK.45 / 18 x 60 Threaded subplates Data sheet 2.9-30

12 154.2603 Knurled nut Ex M18 x 1,5 x 18 Multi-station subplates Data sheet 2.9-60

15 239.2033 Screw plug HB0 (incl. seal) Module type manifold blocks Data sheet 2.9-100 SYMBOL

17 160.2251 O-ring ID 25,07 x 2,62 (NBR) Technical explanations Data sheet 1.0-100 BH22040b BH22041a BH32040b BH32041a

18 160.2170 O-ring ID 17,17 x 1,78 (NBR) Hydraulic fluids Data sheet 1.0-50 A A A A

60 246.2136 Socket head screw M5 x 35 DIN 912 Filtration Data sheet 1.0-50 a a b b a a b b a a b b a a b b

70 160.2093 O-ring ID 9,25 x 1,78 (NBR) „-25 °C to…” Relative duty factor Data sheet 1.1-430 P P P T P T

160.7092 O-ring ID 9,25 x 1,78 (NBR) „-40 °C to…” BH3404

160.6092 O-ring ID 9,25 x 1,78 (FKM)

A

110 111.1080 Cable gland M20 x 1,5

a a o ab b b

P T

COMMISSIONING INSTALLATION NOTES

Attention! When commissioning, the valve must be vented under Mounting type Flange mounting

pressure (max. two rotations of screw E). 4 fixing holes for

socket head screws M5 x 45 TYPE CODE

The solenoid coil must only be put into operation, if the 2/2 or 3/2 way execution B H 2 04 - #

requirements of the operating instructions supplied are Mounting position Any, preferably horizontal 3/4 way execution B H 3 4 04 - #

observed to their full extent. In case of non-observance, Tightening torque Fixing screws M = 5,2 Nm (screw

D

no liability is assumed. quality 8.8, zinc coated) Mounting interface according to Wandfluh standard

M = 9 Nm knurled nut

D

Hand lever

Note! The length of the fixing screw depends on the base

material of the connection element. 2 way (connections) 2

3 way (connections) 3

Attention! For stack assembly please observe the remarks in the 2 switching positions

operating instructions 4 switching positions

Nominal size 4-Mini

Normally closed Hand lever on A-side 1a

Normally open Hand lever on B-side 0b

Sealing material NBR

FKM (Viton) D1

Design index (subject to change)

1.11-5120

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 [email protected]

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 21 18 1.11-3146 E www.wandfluh.com Illustrations are not binding Data subject to change 1/3 Edition: 17 23 1.11-5120 E

Page 622