Page 643 - Softbound_Edition_19_en

P. 643

Poppet valve

Poppet valve

Poppet valve

NG6

Flange construction ISO 4401-03

◆ pneumatically operated

◆ 2/2-, 3/2- und 3/4-way

◆ normally open and normally closed

◆ Q = 40 l/min

max

◆ p = 350 bar

max

DESCRIPTION APPLICATION

Direct operated 2/2-, 3/2 and 3/4-way poppet valve in flange const- Poppet valves are used where tight closing functions of the valve

ruction. By means of the pneumatic actuation control head, the are essential like leakage-free load holding, clamping or gripping.

poppet valve spool is opened or closed acting against the spring.

Due to the poppet spool construction with pressure compensation

on both sides, the flow through the valve is possible in both direc-

tions. The seat spool guide is sealed by means of an O-ring. The

metallically sealing seat closes the valve virtually leak free.

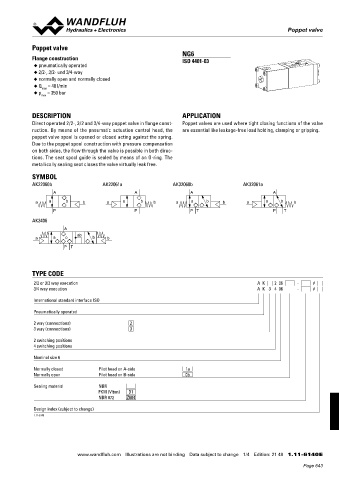

SYMBOL

AK22060b AK22061a AK32060b AK32061a

A A A A

a a b b a a b b a a b b a a b b

P P P T P T

AK3406

A

a a o ab b b

P T

TYPE CODE

2/2 or 3/2 way execution A K 2 06 - #

3/4 way execution A K 3 4 06 - #

International standard interface ISO

Pneumatically operated

2 way (connections) 2

3 way (connections) 3

2 switching positions

4 switching positions

Nominal size 6

Normally closed Pilot head on A-side 1a

Normally open Pilot head on B-side 0b

Sealing material NBR

FKM (Viton) D1

NBR 872 Z604

Design index (subject to change)

1.11-6140

www.wandfluh.com Illustrations are not binding Data subject to change 1/4 Edition: 21 48 1.11-6140 E

Page 643