Page 434 - Softbound_Edition_19_en

P. 434

Proportional spool valve

Proportional spool valve Proportional spool valve

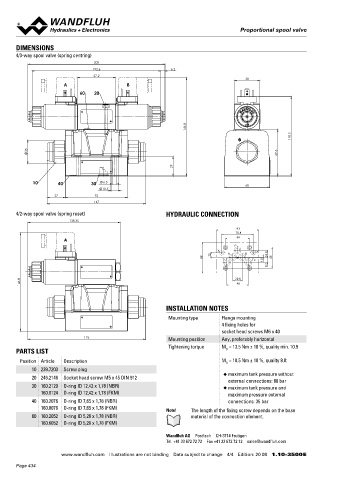

DIMENSIONS Proportional spool valve with integrated

4/3-way spool valve (spring centring) electronics NG10

205 Flange construction ISO 4401-05

192.6 6.2

◆ pilot operated

57.2

38 ◆ Q = 200 l/min

A B ◆ Q max = 90 l/min

N max

60 20 ◆ p = 350 bar

max

146.8 DESCRIPTION APPLICATION

118.3 Pilot operated proportional spool valve with 4 connections in Proportional spool valves are perfectly suitable for demanding

5-chamber system and integrated electronics. Precise spool fit, tasks due to the high resolution, large volume flow and low hystere-

35 69.6 low leakage, long service life time. Very compact construction with sis. Pilot operated valves are used where large volume flows have

corresponding low weight. The pilot valve is a proportional sole- to be controlled. Due to the large flow range and the high stiffness

noid operated pressure reducing valve. The function of the pilot and of the actuation as a result of the pilot control, these valves are

29

main valve as well as the interaction of both valves can be found in suitable for applications where fast acceleration and deceleration

the hydraulic diagram. Proportional to the solenoid current, the processes, high speeds and sensitive motion sequences are requi-

10 40 30 6.5 68 spool stroke, the spool opening and the valve volume flow increase. red. The applications are in the industrial as well as in the mobile

10.5

The control takes place via an analogue interface or a fieldbus hydraulics for the smooth control of hydraulic actuations.

27 93 interface (CANopen, J1939 or Profibus DP). The parameterisation

147 takes place by means of the free of cost parameterisation and diag- Note! „PASO” is a Windows programm in the flow diagram

4/2-way spool valve (spring reset) HYDRAULIC CONNECTION nostics software «PASO» or via fieldbus interface. As an option, style, which enables the intuitive adjustment and storing

138.35 these valves are available with integrated controller. As feedback of all variable parameters. The data remain saved in

case of a power failure and can also be reproduced and

value generators sensors with voltage or current output can be

93 transferred to other DSVs

70.8 connected directly. The available controller structures are optimi -

A 54 sed for applications with hydraulic actuations.

P

X A B Y

68 12 T To 1.5 16.8 46

9.7

SYMBOL

146.8 20.8 Symmetrical control

48

BCA-S BC1-S CA2-S

A B A B A B

INSTALLATION NOTES a 0 b a b

a b a b

Mounting type Flange mounting

4 fixing holes for P T P T P T

socket head screws M6 x 40

176 Mounting position Any, preferably horizontal Meter-in control

Tightening torque M = 13.5 Nm ± 10 %, quality min. 10.9 BDA-V BD1-V DA2-V

PARTS LIST D A B A B A B

Position Article Description M = 10.5 Nm ± 10 %, quality 8.8: 0

D

10 239.7203 Screw plug a a b b a a b b

◆ maximum tank pressure without

20 246.2146 Socket head screw M5 x 45 DIN 912 P T P T P T

external connections: 80 bar

30 160.2120 O-ring ID 12,42 x 1,78 (NBR) ◆ maximum tank pressure and

160.8124 O-ring ID 12,42 x 1,78 (FKM) maximum pressure external

40 160.2076 O-ring ID 7,65 x 1,78 (NBR) connections: 35 bar

160.8076 O-ring ID 7,65 x 1,78 (FKM) Note! The length of the fixing screw depends on the base

60 160.2052 O-ring ID 5,28 x 1,78 (NBR) material of the connection element.

160.6052 O-ring ID 5,28 x 1,78 (FKM)

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 [email protected]

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 20 08 1.10-3500 E www.wandfluh.com Illustrations are not binding Data subject to change 1/6 Edition: 18 41 1.10-3510 E

Page 434