Page 488 - Softbound_Edition_19_en

P. 488

Poppet valve

Poppet valve cartridge Poppet valve

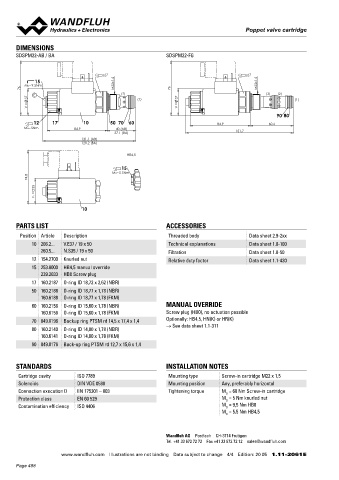

DIMENSIONS Solenoid operated poppet valve cartridge

SDSPM22-AB / BA SDSPM22-FG ◆ solenoid actuated M22 x 1,5

◆ direct operated ISO 7789

◆ 2/2- or 3/2-way

s27 s27 ◆ Q = 40 l/min x II 2 G Ex db IIC T6, T4

max

15 p = 350 bar x II 2 D Ex tb III C T80 °C, T130 °C

MD= 9.5Nm M22x1.5 M22x1.5 ◆ max x I M2 Ex db I Mb

76 76

E (2) (3) (2) Class I Division 1

37 (1) 37 (1) Class I Zone 1

V = V =

90 80

12 17 10 50 70 60 84.9 60.6

MD=5Nm 84.9 40 (AB)

37.1 (BA) 151.7

131.1 (AB) DESCRIPTION APPLICATION

128.2 (BA)

Direct operated 2/2- and 3/2-way solenoid poppet valve in screw-in These valves are suitable for applications in explosion-hazard

HB4,5 cartridge construction for cavity according to ISO 7789. By means areas, open cast and also in mines. Poppet valves are used where

of the pressure tight switching solenoid, the pressure compen- tight closing functions of the valve are essential like leakage-free

15 sated, metallically sealing poppet spool is either opened or closed. load holding, clamping or gripping. For machining the cartridge

MD=5.5Nm The seat spool guide is sealed by means of an O-ring. The pressure cavity in steel and aluminum blocks, cavity tools are available (hire

74.8 tight encapsulated Ex-protection solenoid coil prevents an explo- or purchase). Please refer to the data sheets in register 2.13.

35 sion on the inside penetrating to the outside as well as an ignitable

N = surface temperature.

10

PARTS LIST ACCESSORIES

Position Article Description Threaded body Data sheet 2.9-2xx CERTIFICATES ACTUATION

10 206.2... V.E37 / 19 x 50 Technical explanations Data sheet 1.0-100 Surface Mining Standard Z604 Actuation Switching solenoid, wet pin push type,

260.5... N.S35 / 19 x 50 Filtration Data sheet 1.0-50 -25 °C to… -40 °C to… pressure tight

12 154.2700 Knurled nut Relative duty factor Data sheet 1.1-430 ATEX x x x x Execution MKY45 / 18x60 (data sheet 1.1-183)

15 253.8000 HB4,5 manual override IECEx x x x x MKU45 / 18x60 (data sheet 1.1-184)

239.2033 HB0 Screw plug CCC x x x x Connection Cable gland for cable Ø 6,5…14 mm

17 160.2187 O-ring ID 18,72 x 2,62 (NBR) EAC x x x x Attention! The UL execution is always supplied without cable

50 160.2188 O-ring ID 18,77 x 1,78 (NBR) Australia x x x x gland

160.6188 O-ring ID 18,77 x 1,78 (FKM) MA x x

60 160.2156 O-ring ID 15,60 x 1,78 (NBR) MANUAL OVERRIDE UL / CSA x x x

160.6156 O-ring ID 15,60 x 1,78 (FKM) Screw plug (HB0), no actuation possible

70 049.8196 Backup ring PTSM rd 14,5 x 17,4 x 1,4 Optionally: HB4,5, HN(K) or HR(K) The certificates can be found on www.wandfluh.com

→ See data sheet 1.1-311

80 160.2140 O-ring ID 14,00 x 1,78 (NBR)

160.6141 O-ring ID 14,00 x 1,78 (FKM)

90 049.8176 Back-up ring PTSM rd 12,7 x 15,6 x 1,4

SYMBOL

STANDARDS INSTALLATION NOTES „Normally open“ AB „Normally closed“ BA FG

Cartridge cavity ISO 7789 Mounting type Screw-in cartridge M22 x 1,5 2 2 2

Solenoids DIN VDE 0580 Mounting position Any, preferably horizontal a b a b a b

Connection execution D EN 175301 – 803 Tightening torque M = 60 Nm Screw-in cartridge 1 1 3 1

D

Protection class EN 60 529 M = 5 Nm knurled nut

D

Contamination efficiency ISO 4406 M = 9,5 Nm HB0

D

M = 5,5 Nm HB4,5

D

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 [email protected]

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 20 05 1.11-2061 E www.wandfluh.com Illustrations are not binding Data subject to change 1/5 Edition: 23 05 1.11-2064 E

Page 488